Ewellix is a pioneer in the technology of roller screws and offers high quality, high performance and the widest assortment of roller screws available on the market.

The Ewellix in–house highly integrated manufacturing process uses the latest machining technology including soft and hard machining, heat treatment (induction and through hardening), grinding and assembly operations. Ewellix manufacturing facilities also house laboratories dedicated to life tests, tribology, noise measurement and metallurgy. Beyond the standard assortment made from high grade bearing steel, Ewellix offers special variants with stainless steel and high temperature steel combined with coatings, etc. to respond to the most demanding applications.

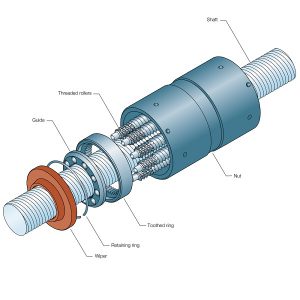

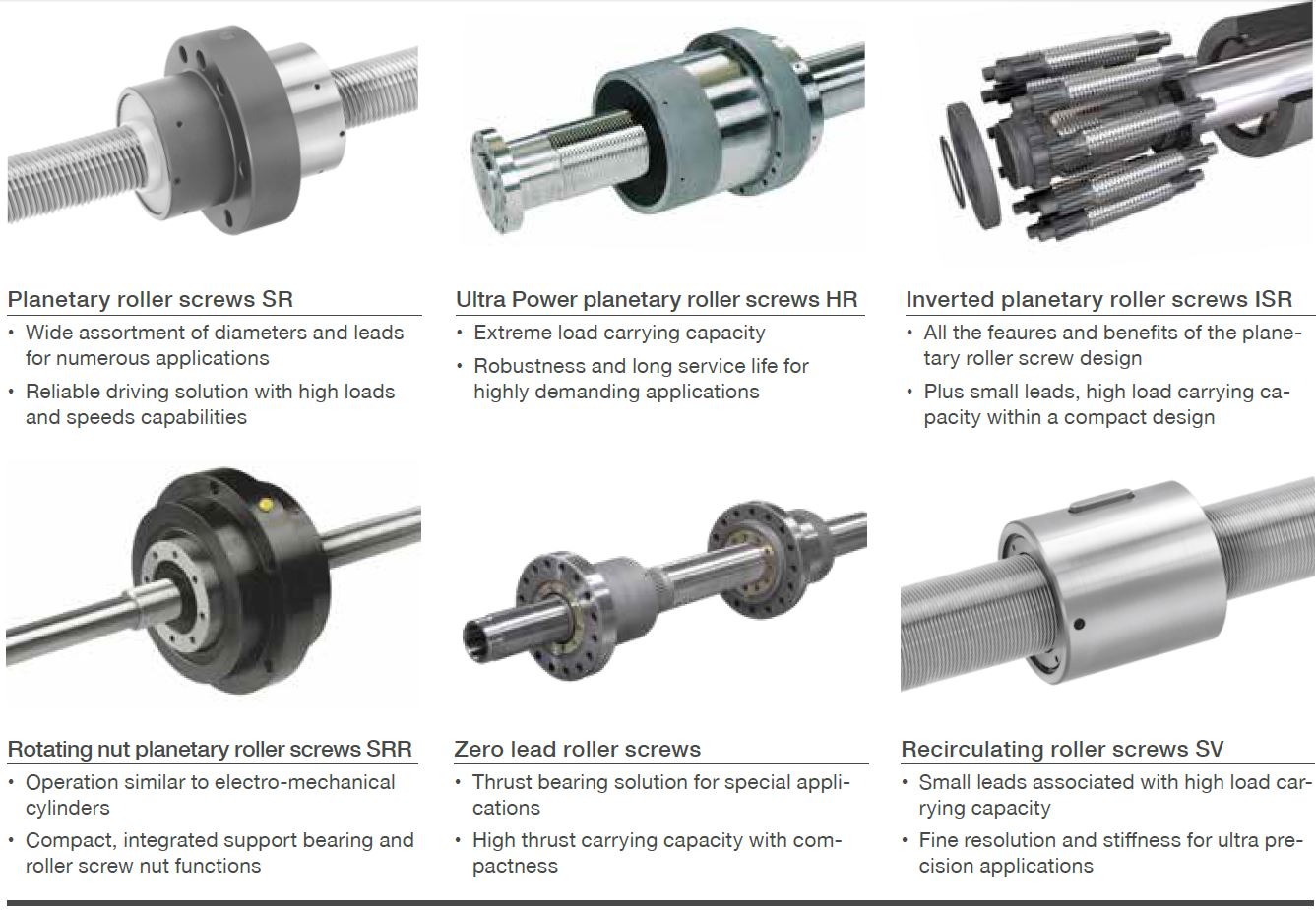

Ewellix offers three main variants of planetary roller screws that do not require roller recirculation:

- The traditional SR assortment with threaded rollers synchronized to the nut, thanks to identical helix angle for the rollers and the nut

- The HR Ultra Power roller screws with increased capabilities compared to the SR assortment

- The ISR inverted roller screws with threaded rollers synchronized to the screw shaft, thanks to identical helix angle for the rollers and the shaft.

In addition, Ewellix offers special variants of planetary roller screws:

- The SRR rotating nut roller screws

- Zero lead roller screws that can advantageously replace a traditional thrust bearing solution when extreme axial load carrying capacity, low weight and compactness are required.

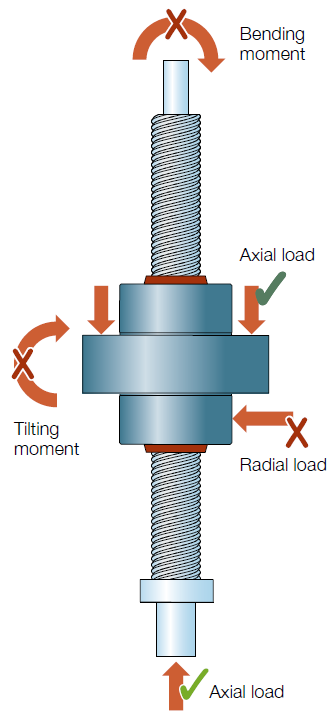

Ewellix offers a wide assortment of recirculating roller screws. Since the rollers are circumferentially grooved, after each complete revolution around the nut, the grooved rollers must be recirculated back to their starting point on one side of the nut, with the help of cams and axial groove inside the nut.

Small leads are possible with a relatively larger thread pitch on the shaft and nut. This feature offers the ideal combination of small lead, high load carrying capacity, a high degree of stiffness and precision.

Nevertheless, the recirculating roller screws present lower speed and acceleration capabilities than planetary roller screws.

Các loại trục vít con lăn hành tinh Ewellix

|

Expectations with electro–mechanical actuation |

Ewellix roller screw solutions |

|

Increased productivity for industrial grade applications with operational duty cycle over 70% |

High load carrying capacity and cycling capability Accommodate high accelerations and high speeds |

|

Up to 70% energy savings compared to hydraulic and pneumatic actuation technologies |

Mechanical efficiency usually greater than 80% |

|

Functionality, flexibility and controllability |

Widest assortment of roller screws available on the market Accommodate heavy loads with transportation applications Provide accuracy for positioning applications Custom designs and flexible manufacturing equipment |

|

Reliability |

By design, the planetary roller screw offers greater reliability than other driving solutions |

|

Higher repeatability and process stability |

Limited wear, in particular for screws that have been run in at the factory |

|

Easy integration into work cells and existing systems |

High power density |

|

Higher degree of precision |

High degree of positioning accuracy further increased without backlash or with preload Recirculating roller screws with small leads are recommended for ultra–precision applications |

|

Low noise levels |

Very smooth and quiet operation with planetary roller screws |

|

Cleanliness |

Roller screws consume a very small amount of lubricants |

|

Lower total cost of ownership (TCO) compared to traditional types of actuation |

Long service life and reliability |

Trục vít con lăn hành tinh, không tuần hoàn con lăn

Ewellix cung cấp ba biến thể chính của vít con lăn hành tinh, không tuần hoàn con lăn:

• Series SR truyền thống với các con lăn ren được đồng bộ hóa đối với đai ốc, nhờ vào góc xoắn giống nhau cho con lăn và đai ốc.

• Series HR Ultra Power tăng cường khả năng so với Series SR.

• Series con lăn đảo ngược ISR với con lăn ren được đồng bộ hóa với trục vít, nhờ góc xoắn giống hệt nhau cho các con lăn và trục.

Trục vít con lăn hành tinh, tuần hoàn con lăn

Ewellix cung cấp nhiều loại con lăn tuần hoàn. Vì các con lăn được tạo rãnh theo chu vi, sau mỗi vòng quay hoàn chỉnh xung quanh đai ốc, các con lăn có rãnh phải được tuần hoàn trở lại điểm xuất phát của nó ở một bên của đai ốc, với sự trợ giúp của cam và rãnh trục bên trong. Tính năng này cung cấp sự kết hợp lý tưởng nước ren nhỏ, khả năng chịu tải cao, độ cứng và độ chính xác cao. Tuy nhiên, vít con lăn tuần hoàn có mặt thấp hơn tốc độ và khả năng tăng tốc hơn con lăn hành tinh.

| Trục vít con lăn hành tinh Roller Screws | Đường kính trục | Lead | Chiều dài tối đa | Cấp chính xác |

| SRC/BRC planetary roller screws with cylindrical nut | 8 – 30 mm | 2 – 20 mm | 2 mét | G1, G3, G5 |

| SRC/BRC planetary roller screws with cylindrical nut | 36 – 56 mm | 6 – 30 mm | 4 mét | G1, G3, G5 |

| SRC/BRC planetary roller screws with cylindrical nut | 60 – 120 mm | 10 – 42 mm | 8 mét | G1, G3, G5 |

| SRF/BRF/SRP/BRP planetary roller screws with flanged nut | 8 – 30 mm | 4 – 20 mm | 2 mét | G1, G3, G5 |

| SRF/BRF/SRP/BRP planetary roller screws with flanged nut | 36 – 56 mm | 6 – 36 mm | 4 mét | G1, G3, G5 |

| SRF/BRF/SRP/BRP planetary roller screws with flanged nut | 60 – 120 mm | 10 – 42 mm | 8 mét | G1, G3, G5 |

| PRU preloaded planetary roller screws with cylindrical nut | 8 – 30 mm | 2 – 20 mm | 1.6 mét | G1, G3, G5 |

| PRU preloaded planetary roller screws with cylindrical nut | 36 – 56 mm | 6 – 36 mm | 3.1 mét | G1, G3, G5 |

| PRU preloaded planetary roller screws with cylindrical nut | 60 – 64 mm | 10 – 36 mm | 3.65 mét | G1, G3, G5 |

| PRK preloaded planetary roller screws with flanged nut | 8 – 36 mm | 4 – 24 mm | 1.9 mét | G1, G3, G5 |

| PRK preloaded planetary roller screws with flanged nut | 39 – 64 mm | 5 – 36 mm | 3.65 mét | G1, G3, G5 |

| HRC Ultra Power planetary roller screws with cylindrical nut | 60 – 120 mm | 15 – 40 mm | 8 mét | G1, G3, G5 |

| HRC Ultra Power planetary roller screws with cylindrical nut | 135 – 240 mm | 15 – 50 mm | 8 mét | G1, G3, G5 |

| HRF/HRP Ultra Power planetary roller screws with flanged nut | 60 – 120 mm | 15 – 40 mm | 8 mét | G1, G3, G5 |

| HRF/HRP Ultra Power planetary roller screws with flanged nut | 135 – 240 mm | 15 – 50 mm | 8 mét | G1, G3, G5 |

| ISR inverted roller screws | 18 – 48 mm | G1, G3, G5 | ||

| SRR/BRR planetary roller screws with rotating nut | 25 – 60 mm | 5 – 25 mm | 4.25 mét | G1, G3, G5 |

Ưu điểm của trục vít con lăn roller screw

The Ewellix preferred range encompasses the most frequently used sizes of planetary roller screws and recirculating roller screws. Within that assortment, standard size nuts are stocked at Ewellix factories in Europe and North America for improved availability, greater value, and shorter delivery times. Shafts are manufactured according to customer requirements.

|

Design and manufacturing operations |

• Standard roller screws with standard and maximum load ratings are available with axial play (SR or SV prefix), or without backlash (BR or BV prefix) • Nut dimensions are detailed hereafter • Standard shaft end machining can include turning, milling and grinding operations • End machining is available for Ewellix support bearings |

|

Materials |

• For the preferred range, shafts and nuts are manufactured with standard high quality roller screw steel, detailed in the present Ewellix catalogue Roller screws • Stainless steel and special treatments are not available with the preferred range |

|

Capabilities |

• Machining operations such as splines, hollow shaft, etc. are possible, but might require more time to complete • Unless specified, manufacturing tolerances will be according to ISO 3408–3 class 5 • Lead precision is G5 according to ISO standards. G3 and G1 also possible on request • Screw assemblies are shipped with a protective rust inhibitor coating • Special documents can be supplied on request: Certificate of conformity to customer drawings # 1969981, lead precision curve • Matching FLRBU support bearings size 2 to 6 can be delivered with the screws |

|

Export note |

• Product for nuclear, aerospace or military applications may be subject to export restrictions and/or licensing requirements. In such cases, delivery time shall be dependent upon securing approvals from the appropriate overnmental authority. |

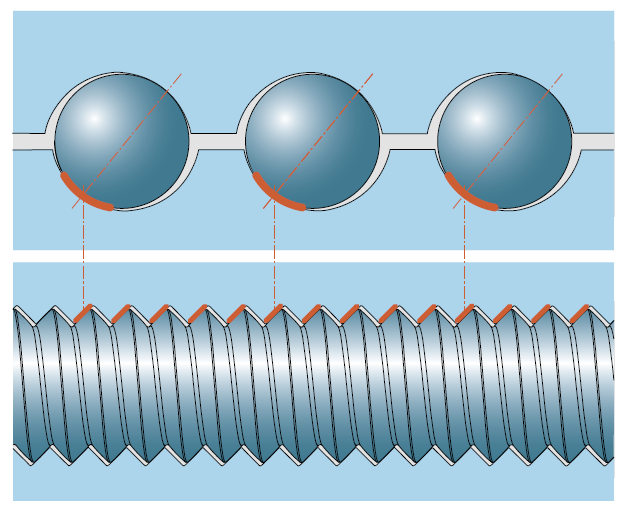

Comparison of ball screws and roller screws contact area

|

Roller screw concept |

Advantages over a ball screw |

User benefits |

|

Large number of contact points |

High load carrying capacity and up to 10 times longer service life |

Lower total cost of ownership (TCO) |

|

Satellite rollers |

Roller screw rotational speeds up to 50% higher than a ball screw with similar carrying capacity. Roller screw acceleration up to 3 times higher. Absence of recirculation eliminating a significant failure mode.

|

Increased speed of operations Higher productivity Higher degree of reliability |

|

Planetary roller screws with small lead (down to 2,00 mm) |

High load carrying capacity compared to ball screws with small lead which are designed with small diameter balls which have low load carring capacity |

High load carrying capacity combined with positioning accuracy and reduced torque requirements |

|

Evenly spaced planetary or recirculating rollers |

Good operation in applications with changes of direction, stable friction torque |

Low noise High degree of reliability |

|

Recirculating roller screws with small lead down to 1 mm |

High load carrying capacity, high axial stiffness that cannot be obtained with a ball screw of similar lead and diameter Very small input torque |

High resolution, high stiffness, long service life, robustness |

Materials, heat treatment and coatings

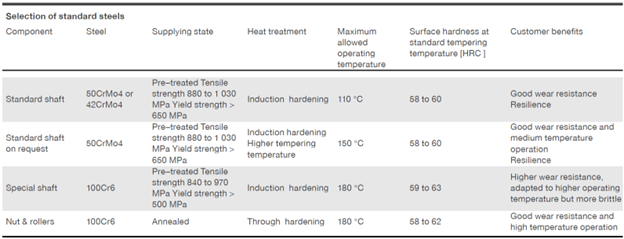

Choice of steel material Standard screw shafts are mainly manufactured from pre– treated 50CrMo4 (otherwise 42CrMo4) which is surface hardened by induction. Through hardened 100Cr6 bearing steel is used for nuts and rollers.

100Cr6 can also be selected for the screw shaft for operation at higher temperature up to 180 °C, or if the application presents a concern for wear.

Material properties are detailed in table below.

Stainless steel can be used for all types of roller screws. Properties offered by these special steel variants are summarized in table below.

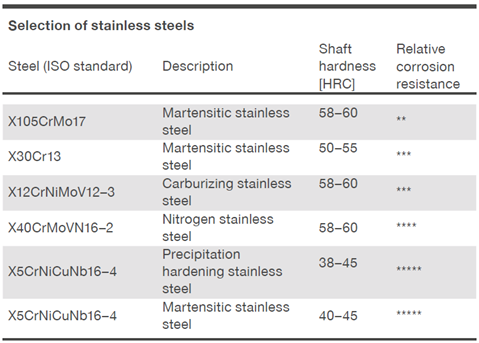

Permissible and prohibited loading on roller screw

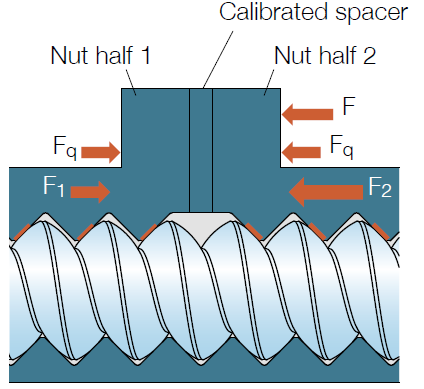

Axial play and preload

Standard roller screws are manufactured with axial play which varies between 0,02 mm and a maximum of 0,1 mm, depending on product size.

Roller screws can be manufactured without backlash or with preload.

- SR Planetary roller screw with axial play

- BR Planetary roller screw without backlash

- PR Planetary roller screw with preloaded split nut

- PRM Planetary roller screw with preloaded double nut

- SV Recirculating roller screw with axial play

- BV Recirculating roller screw without backlash

- PV Recirculating roller screw with preloaded split nut

- PVM Recirculating roller screw with preloaded double nut

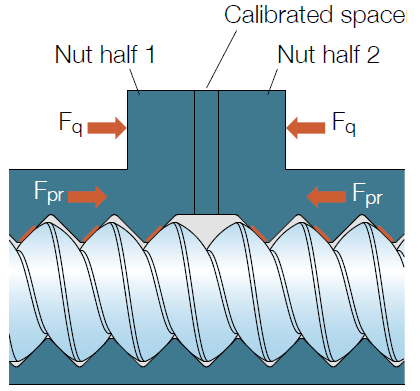

For optimum stiffness and positioning accuracy during reversal of loading direction, or during operation with low external load, internally preloaded nuts are recommended. Under these conditions, preloaded nuts exhibit a much lower axial deflection and much higher stiffness than non– preloaded nuts.

All preloaded roller screws (PR and PV types) are run in before delivery to the customer. This process stabilizes preload and stiffness and virtually eliminates backlash over the service life of the screw.

Preload in a split nut without external load

Preloaded split nut with external force