Profile rail guides – LWR | Thanh dẫn hướng Rail Guide Ewellix được sử dụng rộng rãi trong nhiều ứng dụng khác nhau, yêu cầu độ chính xác cao.

Profile rail guides – LWR

• Ball assemblies of LWRB series.

• Ball assemblies with Anti-Creeping Systemof LWRBACSM series.

• Crossed roller assemblies of standard LWR series.

• Crossed roller assemblies of optimized LWRE series.

• Crossed roller assemblies with Anti-Creeping System ofLWRE ACS series.

• Crossed roller assemblies with Anti-Creeping System ofLWRE ACSM series.

• Needle roller assemblies of LWRM/LWRV series.

• Needle roller assemblies of LWM/LWV series.

• Needle roller assemblies with Anti-Creeping System ofLWM/LWV ACSZ series.

• Slide coating of LWRPM/LWRPV series.

Features and benefits Profile rail guides – LWR

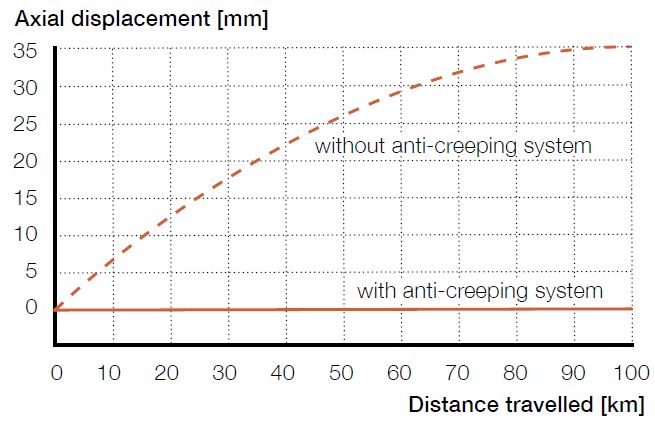

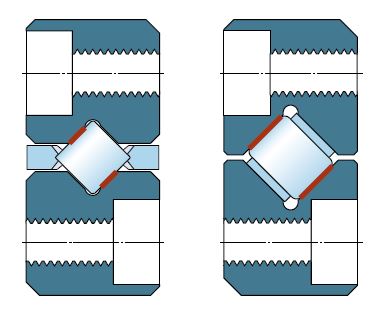

Anti-creeping system

Profile rail guides – LWR Ewellix developed the industry’s first anti-cage-creep solution. It keeps the movement of the rolling element assembly in the required position at the loaded zone, avoids cage creep from high operational speed and acceleration to uneven load distribution and weak adjacent parts, and prevents unplanned downtime and additional maintenance. In addition, due to the defined position of the cage, Ewellix precision rail guides with anti-creeping system, or ACS, enable increased accuracy, higher accelerations (tested up to 160 m/s2) and reliable vertical installation.

Higher load rating and rigidity

Profile rail guides – LWR Compared to conventional LWR precision rail guides, Ewellix optimized the internal geometry and developed LWRE precision rail guides for applications that demand robust performance. Part of our Modular Range, LWRE precision rail guides feature rollers with a 33% larger diameter and utilize the entire roller length than those in LWR rail guides. These LWRE guides offer five times higher load ratings and twice the rigidity in comparison with LWR rail guides. In operation, the increased load rating and rigidity helps to increase process stability and reliability, ultimately extending equipment service life and reducing total cost of ownership.

Extreme accuracy and positioning repeatability

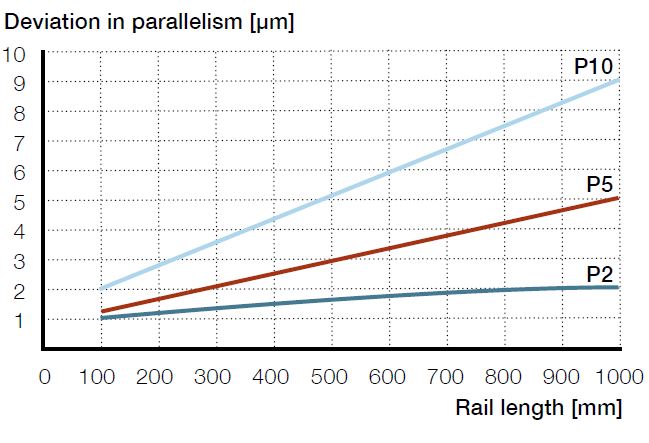

Profile rail guides – LWR Compared to other linear guiding products, precision rail guides provide the highest linear guiding accuracy. Precision rail guides from Ewellix are available in three different precision classes to meet a range of requirements for precision. The increased accuracy and repeatability enables higher productivity and product quality in diverse applications, e.g. semi-conductors, machine tools, measurement and testing equipment, and medical equipment.

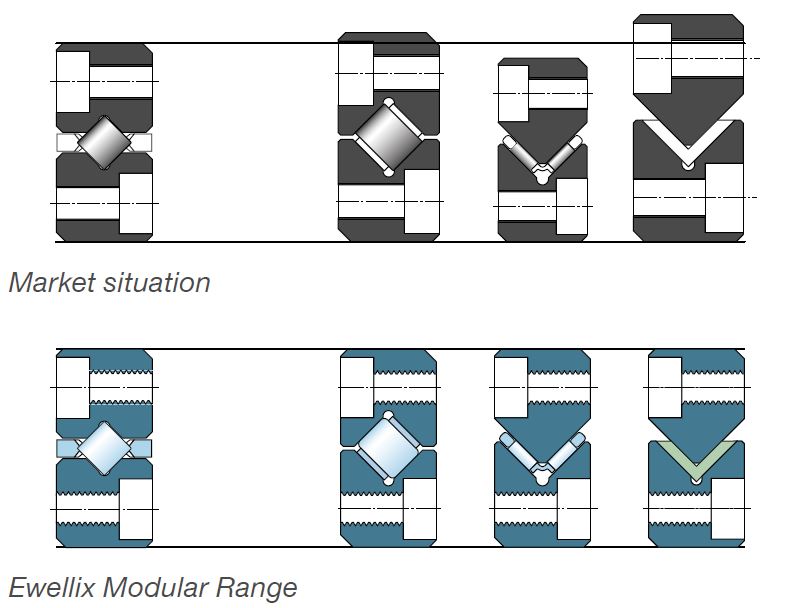

Modular Range With the Ewellix

Profile rail guides – LWR Modular Range of precision rail guides, outer rail dimensions remain the same, but rolling elements are interchangeable to best meet application demands. With this design modularity, customers can easily increase load ratings or extend the rating life without having to redesign the equipment. The Ewellix Modular Range of precision rail guides covers 80% of dimensions on the market. Additionally, the customer can choose between ball assemblies, crossed roller assemblies, crossed roller assemblies with ACS/ACSM, needle roller assemblies and slide coatings.